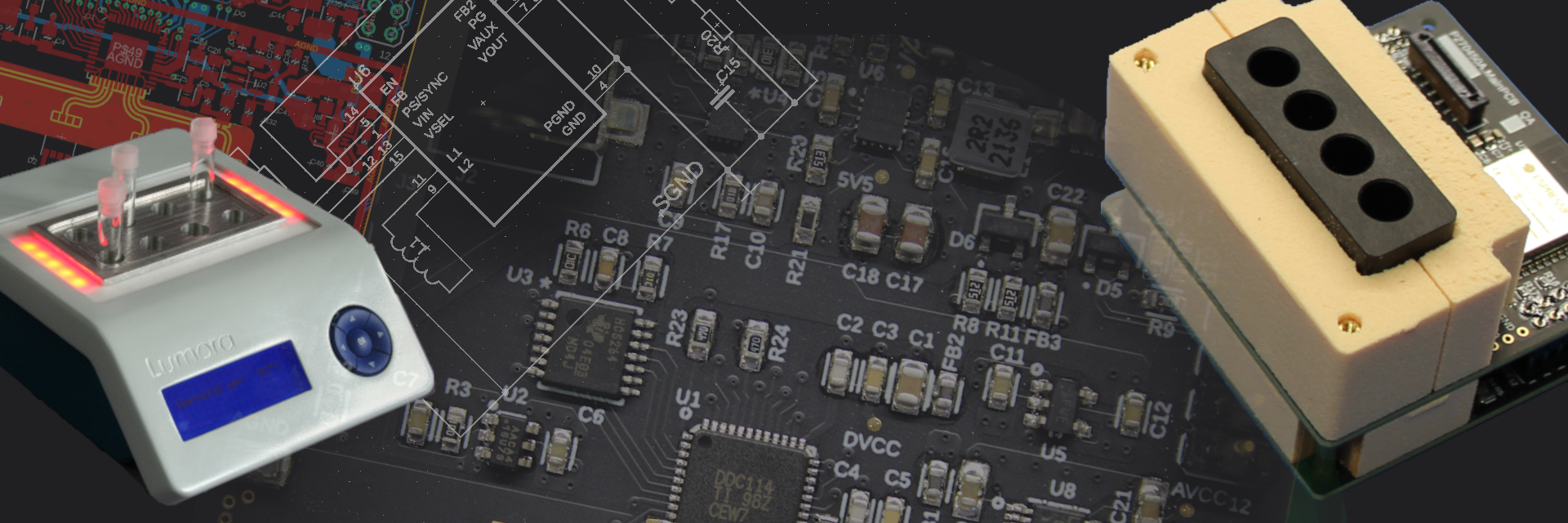

I help organisations design and mature technically demanding products. My work is fundamentally systems-oriented, integrating electronics, mechanics, optics and software into robust solutions that work in the real world.

My clients tend to be technology-driven: they have a core technology but are facing a system-level challenge — where success depends on making the right architectural and embodiment decisions across disciplines. I’m not engaged to supply isolated specialist input, but to take responsibility for how a system comes together and matures.

Projects often span early feasibility and requirements capture through to prototype systems and operational validation, including work in medical devices and other regulated/high-reliability domains.

Though development is broadly structured around the V-model (specify – design – verify), the reality is more iterative and evidence-led than linear. Design inputs, system design and design outputs evolve together as models, prototypes and test results drive revisions to earlier decisions, while maintaining the traceability and control required under ISO 13485.

Design input and problem framing

Many projects start before the challenge is fully defined. I regularly work with clients to clarify user needs, operational context and constraints, and to translate these into clear technical requirements and design inputs.

This early work helps establish a shared understanding of what the system needs to do, what it should not do, and how it is intended to deliver value — before significant design effort is committed.

Typical activities include:

- user needs analysis and intended-use definition

- capture of operational and environmental constraints

- translation of needs into system-level requirements

- early architectural thinking to test assumptions

Systems design and product development

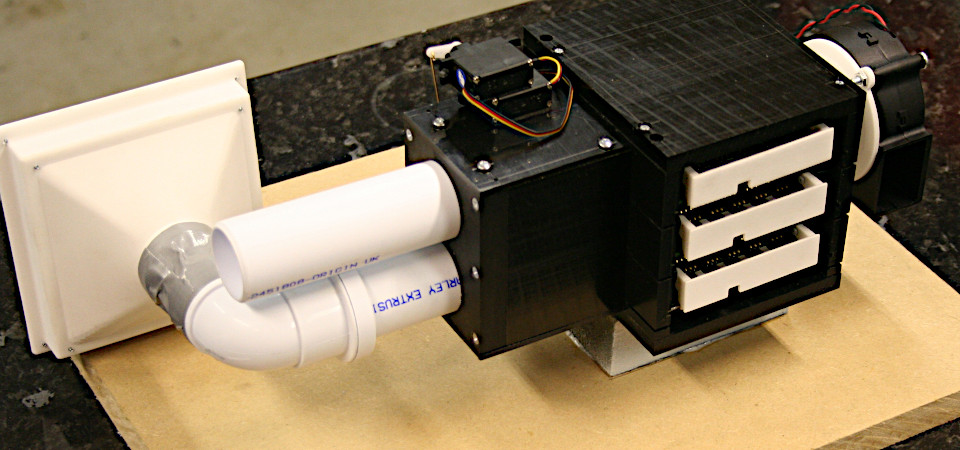

My core work is the design and maturation of complete systems rather than individual components. I work across electronics, mechanics, optics or other physics domains, and firmware, focusing on defining architectures, resolving trade-offs, and ensuring that the system performs reliably in its intended context.

Many of the systems I work on involve detection and measurement. While this often centres on sensors and electronics, many challenges lie in how the complete system behaves once it leaves the lab — how samples are conditioned and presented, variability and interference are managed, measurements are interpreted, and how the whole system responds under real operating conditions.

Typical activities include:

- defining system architectures and interfaces

-

making embodiment decisions that balance performance, cost, size, and robustness

-

integrating electronics, mechanics, physics and software into coherent systems

- iterating designs as requirements, insights and evidence evolve

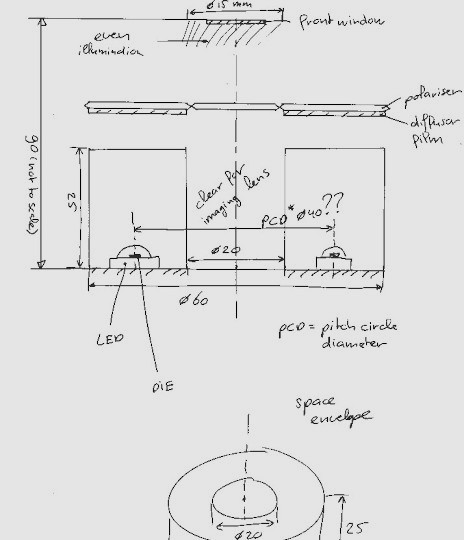

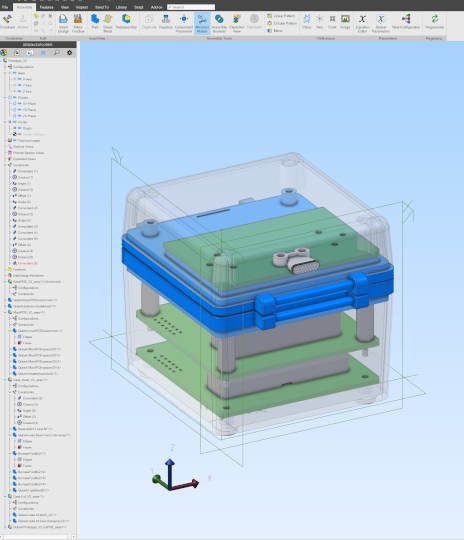

Modelling and prototyping

Technical feasibility studies, virtual models and physical prototypes serve to reduce uncertainty and guide decisions before larger investments are made. The emphasis is on building models and prototypes at the right level of fidelity — detailed enough to answer the questions that matter, but deliberately simplified to expose assumptions, limitations and new questions early.

As designs stabilise, models and prototypes are also used for verification and validation, allowing key behaviours and assumptions to be tested against intended use. These are typically more representative and controlled than early exploratory models, reflecting their different purpose.

This activity typically involves:

- focused experiments and proof-of-concept builds

- rapid mechanical and electronic prototypes

- exploratory test setups and measurements

- comparison of alternative technical approaches

Production readiness, certification and transfer

With functionality validated, the focus shifts from proving that something works to ensuring it can be built, approved and supported reliably. I work with clients to carry systems through this transition, whether the goal is pilot deployment, low-volume early production, or preparation for larger-scale manufacture.

This typically includes:

- refining designs for manufacture and test

- stabilising bills-of-materials, suppliers, and manufacturing processes

- formatting design output for certification and transfer to production

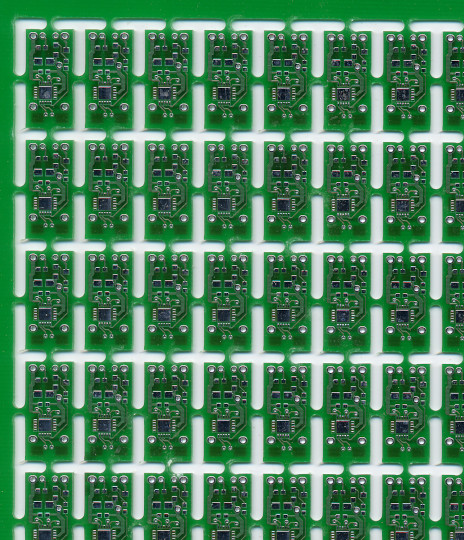

I am not a contract manufacturer, but I regularly support low-volume builds and early production runs, in-house or with external partners. This step is often used to validate assembly processes, test strategies, supply chains and documentation before committing to higher volumes.

Transfer to production is handled pragmatically, working with clients’ manufacturing partners, suppliers and regulatory teams as appropriate. The emphasis is on handing over designs, data and rationale in a form that supports repeatable manufacture, certification and long-term product support, rather than simply delivering a prototype.

Design for regulated and high-reliability environments

Much of my work takes place in regulated contexts, particularly medical device development under ISO 13485, as well as other safety-critical and high-reliability domains. I’m used to working within design controls and producing development records and design rationale that can feed directly into later regulatory submissions.

I’m not a regulatory consultant, but I work closely with clients’ regulatory teams or external specialists to ensure that technical development aligns with regulatory expectations throughout the project.

How to engage

Projects usually begin around a specific system-level challenge or transition, rather than a fully defined brief. An initial conversation is often enough to establish whether there’s a good fit and how best to proceed.